Table of Contents

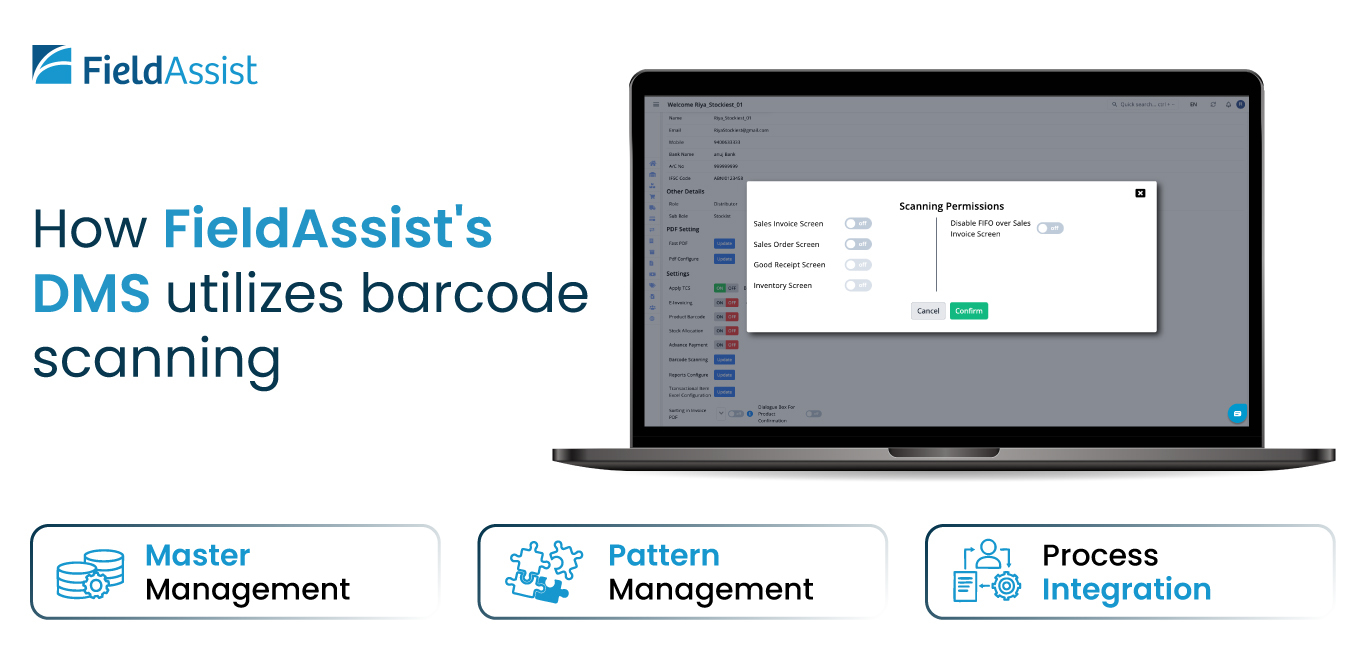

ToggleFor apparel companies, managing inventory and distribution efficiently is key to maintaining smooth operations and meeting consumer demand. When these companies implement FieldAssist’s Distributor Management System (DMS) with barcode scanning, they unlock several operational advantages that can directly impact their productivity and bottom line.

Why barcode scanning matters in a DMS for apparel

Simplified inventory management

Barcode scanning within a DMS provides real-time inventory updates and significantly reduces manual intervention. Apparel and footwear companies often manage diverse product lines with a large number of SKUs involving various sizes, colors, and styles. Barcode scanning ensures:

- Real-Time Accuracy: Inventory levels update automatically with each scan, eliminating stock discrepancies.

- Efficient Stock Audits: Regular inventory checks become faster and more precise, reducing time spent on manual audits.

Improved product traceability

Tracking products from manufacturing to retail is critical in the apparel and footwear sector. A barcode-enabled DMS links products to specific attributes like:

- Fabric or Metarial Type and MRP: Critical for inventory segmentation and pricing accuracy.

- Production Batch Numbers: Enables easy tracing of product origin and quality control.

This level of visibility within the supply chain ensures transparency and supports compliance with quality standards.

Operational benefits for distributors

Efficient order fulfillment

With barcodes integrated into DMS:

- Orders are processed with higher accuracy. Ensuring that the right products are picked and packed for delivery, reducing errors.

- Packing and dispatch workflows are streamlined, reducing turnaround time and improving customer satisfaction.

This means apparel and footwear companies can fulfill more orders in less time, improving customer satisfaction and order turnaround times.

Accurate invoicing and returns

Barcode scanning ensures that every sale and return transaction is captured accurately in the system, with all details (such as product ID, MRP, batch) recorded. Barcode scanning ensures that every product scanned matches the DMS inventory, resulting in:

- Accurate Invoicing – Reducing the possibility of discrepancies between the products delivered and the invoiced amount.

- Simplified Returns Management: When customers return items, barcodes ensure that the return process is fast and accurate, reducing the risk of errors in reverse logistics.

This level of accuracy reduces financial discrepancies and boosts customer trust and loyalty.

Quick distributor onboarding

Barcode scanning also speeds up the onboarding process for new distributors, enabling them to efficiently integrate into the company’s distribution network. By scanning barcodes, they can:

- Quickly Enter Inventory: The process of adding new products to the system becomes faster, saving time and effort compared to manual data entry

- Enable Faster Sales Order Creation: By utilizing barcode scans for sales orders, distributors can enter orders faster and with greater accuracy, reducing bottlenecks in the order-to-fulfillment cycle.

Scalability and long-term impact for apparel businesses

FieldAssist DMS with barcode scanning capabilities enables business growth, offering:

- Scalability for New Markets: Easily supports expanding product lines and distribution networks.

- Future-Ready Operations: Adaptability to new barcode technologies ensures the system remains efficient as the business evolves.

Cost savings and productivity gains:

By reducing manual processes and errors, FieldAssist DMS with barcode scanning not only lowers operational costs but also allows teams to focus on strategic initiatives like market expansion and customer engagement.

Conclusion: Why apparel companies need barcode scanning in their DMS

For apparel companies, the integration of barcode scanning in their Distributor Management System is a game-changer. It provides an all-in-one solution to optimize inventory management, improve tracking and simplify workflows while supporting scalability and cost savings.

By embracing this technology, apparel and footwear companies can empower their distributors, ensure customer satisfaction, and secure a competitive edge in a demanding market. It’s not just a tool – it’s a strategy for long-term success.

About Post Author

Deepshri Somani

Deepshri is a product marketing professional passionate about enterprise SaaS and the transformative role of technology in business success. Outside of work, she enjoys exploring culinary delights and advocates for a minimalist and sustainable lifestyle, emphasizing health and wellness.